EN : Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia conse quuntur magni dolores eos quit.

Project development and industrialization

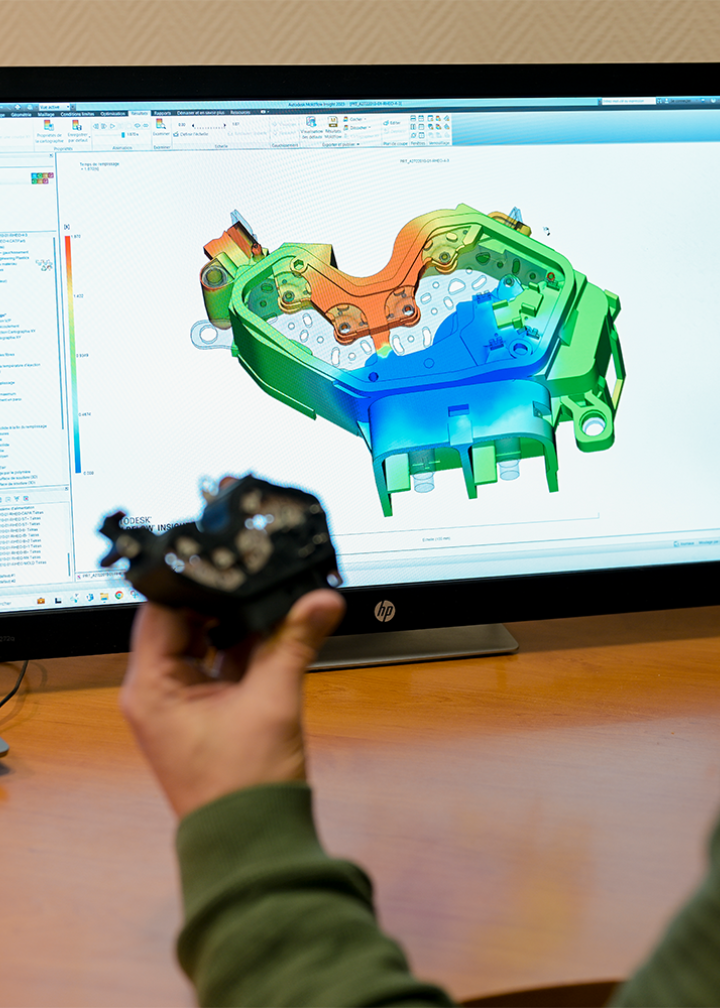

The solutions we implement stem from 45 years of co-design experience and are systematically validated by simulation results conducted in-house.

(fatigue resistance, resonance frequency, stress concentration)

Simulation of plastic flow within the mold

Aiming for excellence.

Our development teams (quality, tooling, industrialization, and projects), around 120 people contribute to quotations, feasibility reviews, and project development.

Our goals: minimize development time and optimize feedback, aiming for state-of-the-art standards.

Project managers lead multidisciplinary teams and serve as primary contacts for our clients.

The quality department ensures compliance with internal and external specifications throughout the project development, up to its transfer to serial production. A team of metrologists and a metrology laboratory are dedicated to measuring parts under development. The department is also self-sufficient in designing its inspection devices.

The tooling department is responsible for design validation, monitoring the manufacturing, testing, fine tuning, and validation of stamping and plastic injection tools. Part of our tools are produced internally, while the remainder is outsourced and supervised externally.

The industrialization department is fully autonomous in design, automation, robotics, manufacturing, and assembly of our processes. A major and differentiating asset to meet our customers needs and gain flexibility during both development and serial production phases. Constantly seeking solutions to enhance our processes, technological watch lies at the heart of our concerns.