EN : Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia conse quuntur magni dolores eos quit.

Technologies

Our Technologies

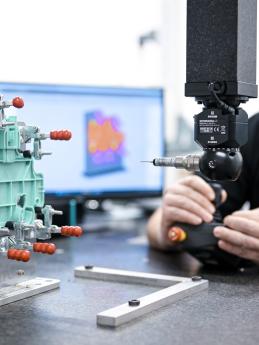

In the realm of industrial equipment, certain innovations have the power to improve production performance and add value to the final product: innovations designed with and for the client.

For the best and the useful.

In the realm of industrial equipment, certain innovations have the power to improve production performance and add value to the final product: innovations designed with and for the client. By applying this collaborative approach, we have developed new design and testing capabilities, implemented new processes for stamping complex shapes, built assembly lines and tools that were previously lacking, and experimented with material combinations. We take pride in these small or large collective advancements.

And, the good news is, the story of our improvement continues.

Stamping

Press tonnage ranges from 100 to 800t

Material thickness cut ranges from 0.2 to 6 mm

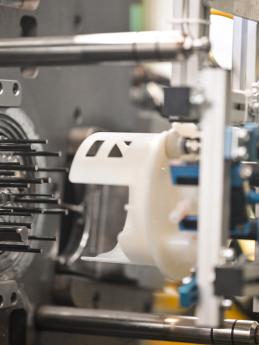

Thermoplastic Injection / Overmolding

Press tonnage ranges from 25 to 500t

Bi-injection

Surface treatments

Internal: epoxy powder coating/ Autophoretic Chemical Coating (ACC)

Outsourced: all types of coatings and plating

Thermal treatments

Inline quenching and tempering

Robotic welding

Resistance welding, arc welding (MAG, TIG, etc.), ultrasonic welding, laser welding

Automated assembly

Integration of all types of components and technologies: crimping, bonding, marking, etc.